Large Optics Capability

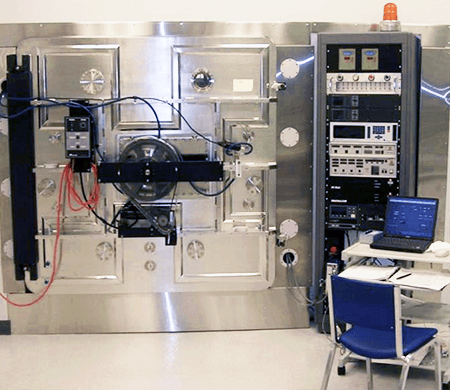

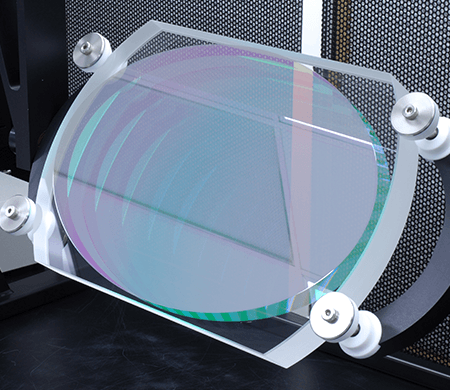

Ion Beam Sputtered coatings are the coatings of choice for applications where low loss is mandatory. And now, MLD has made IBS coatings available for Large Optics. Ion Beam Sputtering surpasses other physical vapor deposition techniques by offering amorphous microstructure, high purity films, exceptional stoichiometry, low deposition temperature and fine control of layer thickness. These process advantages make possible the laser damage resistance, low absorption and low scatter coatings which are critical for so many demanding applications and high level programs.

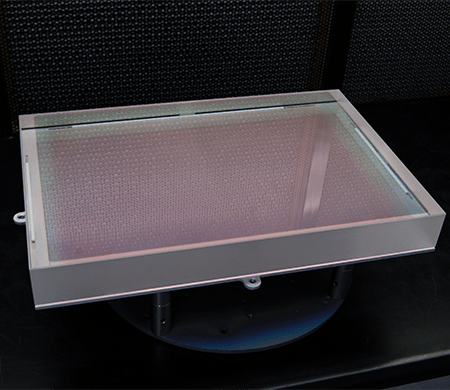

MLD has developed its Large Optics capability to address the need for IBS coatings on substrates up to 20” diameter. With non-uniformity less than 1% across the clear aperture of the optic, a R>99.998% high reflector will retain its performance across the entire coated aperture. With a variety of material choices and a wavelength range spanning 200-5000 nm (UV-NIR), MLD provides a unique capability and a wide array of custom design possibilities for optical systems employing large aperture optics. Our cleaning and inspection facilities were specially developed to support the handling of large optics.

To verify our work, MLD has built an outstanding metrology laboratory. Large optics, especially ones which are non-circular in shape, may need specialized stress compensation. MLD has the ability to measure surface flatness, surface figure and transmitted wavefront. We own phase shifting interferometers which can fully characterize apertures up to 12” in diameter at 1064 and 1319 nm and precision reference flats for use with uncoated and coated substrates. In addition, MLD’s large-optics spectrophotometer, with a translation stage, allows measurement of spectral performance for a large optic over a broad wavelength range.