MLD Technologies Introduces Large-Scale Reflective Coatings for High-Energy Laser and Directed Energy Systems.

Mountain View, CA. – Jan 10, 2025 – MLD Technologies, LLC, a leader in advanced optical coating technologies, proudly announces the expansion of its optical coating capability to include larger and heavier optical components designed for high-energy laser (HEL) and directed energy applications. With proven expertise in low-loss, multi-wavelength high reflectors, MLD’s new capability further reinforces its position as a trusted partner for cutting-edge optical solutions.

Advanced Expertise in Coating Materials The choice of coating materials is a critical factor in the design and manufacture of optical coatings for applications where performance is paramount. MLD has over 25 years of experience in Ion Beam Sputtering (IBS) of HfO2, Ta2O5, Nb2O5, ZrO2, TiO2, Al2O3, SiO2, and other metal-oxides. This expertise across a very broad range of materials expands design possibilities, enabling optimal solutions tailored to specific optical and power requirements.

“This capability enables us to scale production while maintaining the precision and performance standards that our customers demand,” said Len Mott, President, MLD Technologies, LLC. “This milestone reflects our ongoing commitment to innovation and to achieving the requirements of HEL and directed energy systems worldwide.”

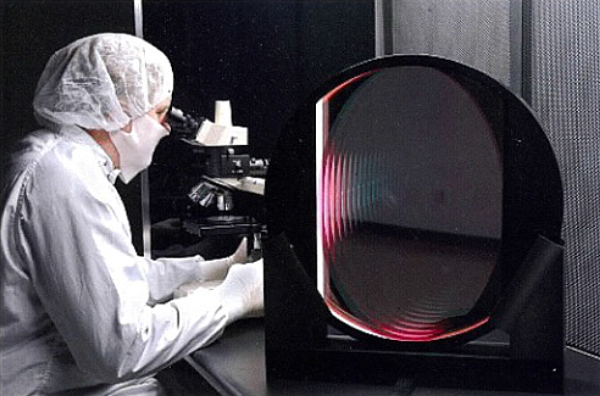

Proven Performance in HEL Applications For more than two decades, MLD has been producing HEL mirrors via ion beam sputtering for diverse applications, handling optics up to 50 cm in diameter and weighing up to 70 kilograms. The capability extends MLD’s expertise to even larger and heavier components, addressing the evolving needs of high-energy laser systems. Current research focuses on further enhancing laser damage resistance through IBS process innovation and testing.

Highlighted Product Capabilities

| Parameter | Performance |

| Optical Losses | < 0.001% |

| Scattering | < 0.001% |

| Damage Threshold – pulsed | > 80 J/cm² at 1064 nm @ 10 ns |

| Damage Threshold – CW | > 5 MW/cm² at 1064 nm – 1mm spot |

| Mirror Reflectivity | > 99.999% @ 1064 nm |

| AR Coating Reflectivity | < 0.01% @ 1064 nm |

Environmental Durability Passed 1,000-hour humidity and thermal cycling tests

Game-Changing Capabilities for Customers MLD’s expertise in complex designs tailored to customers’ unique needs allows the company to produce high-quality, high-performance coatings that often exceed requirements. By minimizing optical losses and improving resistance to laser-induced damage, MLD’s solutions maximize the efficiency and longevity of critical optical systems in defense, aerospace, semiconductor equipment and medical device industries.

Strategic Partnership Opportunities This enhanced optical coating capability, developed with proprietary, MLD-designed IBS Chambers, strengthens MLD’s strategic value to companies seeking horizontal or vertical integration of advanced optical technologies. By offering uniquely high-performing coatings and larger optical components, MLD creates opportunities for strategic partners to expand their product portfolios and gain a competitive edge in laser and photonics markets.

Availability The optical coating capability and HEL mirrors are available now. For more information about these capabilities and MLD’s advanced technologies, please visit www.mldtech.com, contact Len Mott, President, at lmott@mldtech.com, Ric Shimshock, Program Manager, at rshimshock@mldtech.com or visit us at Photonics West Booth # 4328.About MLD Technologies, LLC

MLD produces high-performance optical coatings and components specializing in the design, development, and manufacture of ion beam sputtered, low optical loss, laser damage resistant, environmentally stable thin films for the UV-VIS-IR spectral region. Applications include lasers, laser devices, non-linear crystals, medical instruments, and other photonic devices.

Learn more about MLD’s capabilities at https://www.mldtech.com